The LattiSolve Solution

Architectured Material Layout for Tailored Performance

At CRG Defense, we understand that modern systems and products demand tools and workflows that accelerate design, assessment, and optimization – helping teams bring high-performance innovation to market faster.

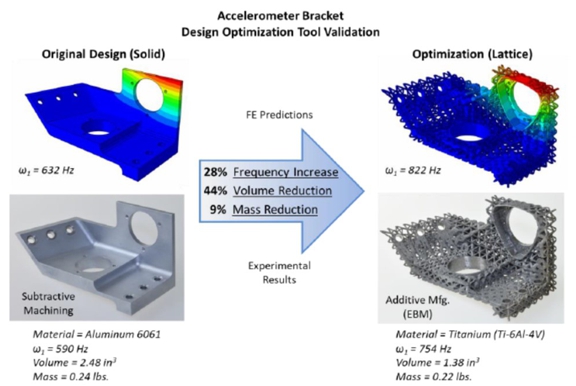

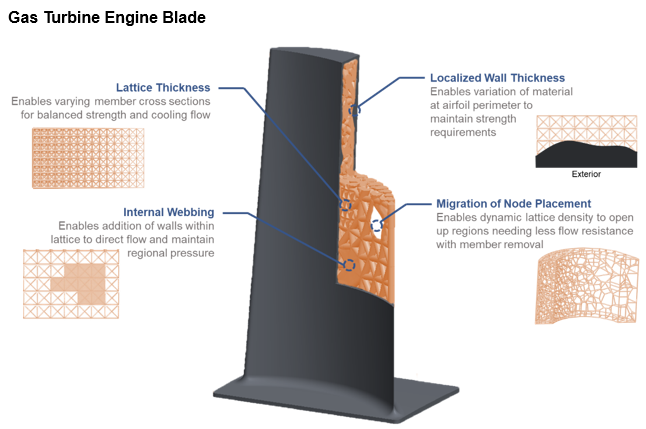

LattiSolve is an advanced computational toolset tailored for design for additive manufacturing (DfAM), specializing in automated lattice generation and architectured material layouts for customized performance. LattiSolve’s proprietary workflow leverages physics-driven, multi-objective topology optimization algorithms and multiphysics simulations to target and address problematic regions vulnerable to structural and thermal loads.

LattiSolve is specifically designed for engineers and designers who need to create and optimize high-performance parts where multifunctional aspects are critical. Its innovative approach enables highly scalable shape optimization, accelerating material placement by considering structural mechanics, fluid dynamics, thermal transport, and other physics-based responses. The result is automated, customized lattice structures capable of maximizing individual objectives or simultaneously optimizing for structural integrity, weight reduction, thermal management, and vibration control.

By prioritizing end-use performance under demanding operational conditions, LattiSolve significantly accelerates the development of innovative, high-performance components. It automates complex optimization processes, enabling rapid prototyping and testing of optimized designs, and dramatically reducing the time required to field new systems or bring products to market. LattiSolve is particularly effective for defense, aerospace, and other high-stakes applications where multifunctional performance is critical.

End-to-End Support

We deliver end-to-end innovation across the research and development (R&D) lifecycle. Our expertise spans from initial concept to final product, encompassing:

- Design

- Prototyping

- Test and evaluation

- Manufacturing

Capabilities

- Multiphysics Design Optimization — Simultaneously optimizes structural integrity, weight reduction, thermal management, and vibration control to create components with multifunctional performance capabilities

- Advanced Functional Tolerancing — Ensures optimized designs meet specific performance requirements by setting tolerances based on thermal, structural, and dynamic functional needs, going beyond basic dimensional tolerances

- Field-Driven Design Approach — Dynamically optimizes geometry and structure using high-fidelity Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) simulation data, incorporating multiphysics fields such as stress distributions, temperature gradients, and fluid flow patterns

- Advanced Lattice Design Integration — Integrates and optimizes custom lattices and unit cells including Triply Periodic Minimal Surfaces (TPMS)

- Intelligent Part Consolidation — Redesigns and consolidates multi-component assemblies into single, integrated parts, improving performance, enhancing reliability, and increasing production efficiency in complex systems

- Accelerated Design-to-Production Cycle — Automates manual iterations, complex simulations, and extensive testing to deliver optimized designs faster to expedite product launch timelines

Applications

- Aerospace & Defense

- Turbine / Engine Components

- Space, Satellite, & Spacecraft Structures

- Hypersonics (Propulsion & Thermal Systems)

- Thermal Management & Heat Exchangers

- Directed Energy Systems

- UAV Stabilization / Sensor Enclosures

- Next Generation Ground Vehicles

- Air Ducts

- Data Centers (Cooling Systems)

- EV / eVTOL Battery Structures

- Motorsports