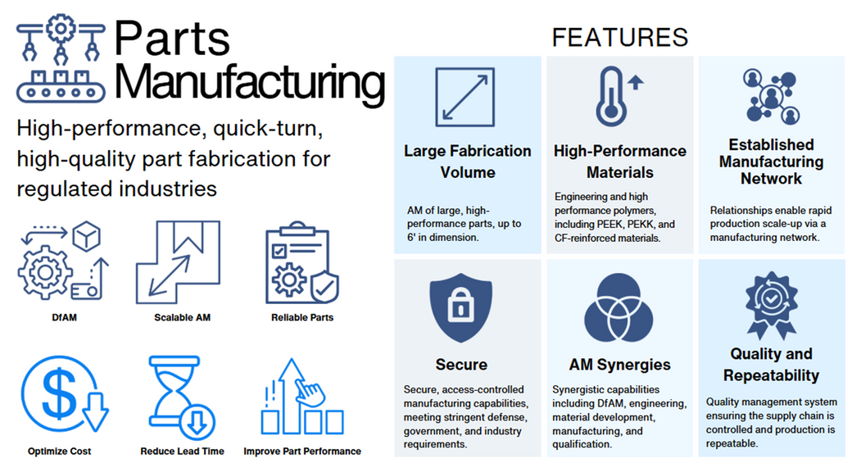

From Concept to Combat-Ready: Scalable AM Solutions Built for Defense and Dual-Use Innovation

Overview

At CRG Defense, additive manufacturing (AM) is not just a capability—it’s a strategic enabler. With nearly 30 years of defense-grade R&D and production experience, we deliver vertically integrated AM services spanning design, materials, prototyping, testing, and full-rate production. Our secure and ISO 9001:2015 / AS9100D-compliant infrastructure supports both internal system development and external customer applications.

Our Capabilities

Design & Simulation Engineering

Our engineering services bridge concept to production through:

- CAD modeling (SolidWorks, CATIA)

- Finite element analysis (FEA) and computational fluid dynamics (CFD)

- Topology optimization and lattice structure design (via LattiSolve)

- Design for additive manufacturing (DfAM) for both polymer and metal parts

- Reverse engineering and assembly consolidation

Outcome: Optimized part geometries that reduce weight, increase strength, and minimize production complexity.

Additive Manufacturing Capabilities (PDF)

Contact UsAdvanced Materials Development

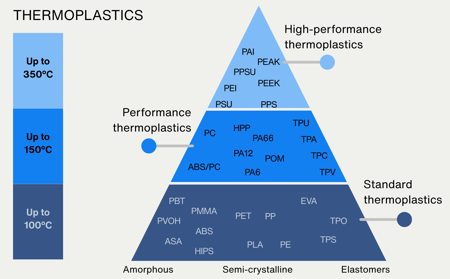

CRG Defense uniquely develops and qualifies its own high-performance additive manufacturing polymers and composites:

- In-house synthesis and formulation (1–100 L reactor scale)

- Lab-scale filament and pellet production (extruders, winders, mills)

- Full thermal, mechanical, and chemical characterization

We specialize in engineering-grade materials like PEEK, PAEK, Ultem, and advanced nylons—optimized for mission-critical applications.

Outcome: Tailored materials for structural, thermal, and chemical resilience in defense environments.

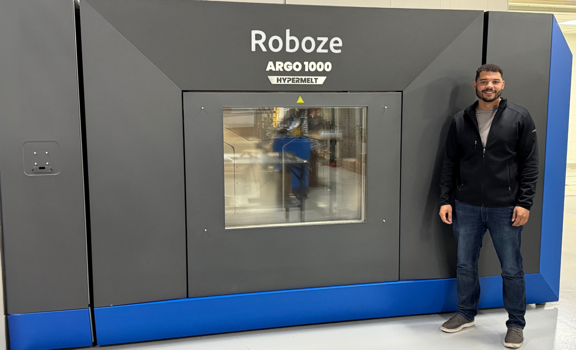

Contact UsMulti-Scale Fabrication

We maintain a scalable and flexible additive manufacturing ecosystem:

- Roboze ARGO 1000 HyperMelt (pellet-fed): 1m³ build volume | 2000 g/hr | Aerospace-grade materials

- Large format FFF (>1m² x 2m): Rapid mock-ups and multi-material prints

- Medium format FFF and FGF: Bridge-scale production and material evaluation

- Fleet of desktop printers: Low-volume, fast-iteration support

- Metal AM (DMLS, DED, WAAM) available via trusted external partners

Outcome: Fast, localized production—from prototypes to production-grade components.

Contact Us

Post-Processing & Precision Finishing

We deliver application-ready components through:

- Support removal, surface sanding, heat treatment

- 3D scanning and dimensional inspection

- 5-axis CNC machining (HAAS, pre-commercial)

- QA/QC with Certificate of Conformance (CoC) or Analysis (CoA)

Outcome: Final parts that meet or exceed defense manufacturing standards.

Contact UsMaterial & Part Qualification

We offer comprehensive testing and validation:

- Tensile, compression, flexural, fatigue, and impact testing

- DMA, SEM, FTIR, DSC, TGA, CT-scan (external), UL-94 flammability

- Environmental testing (thermal cycling, humidity)

- Statistically representative test sampling and evaluation

Outcome: Full traceability and documentation for flight, field, and mission deployment.

Contact UsWhy CRG Defense for Additive Manufacturing?

- Secure Infrastructure: ITAR-compliant, defense-ready campus

- DoD Platform Integration: Supporting internal units across Materiel, Power, and Systems divisions

- Custom Polymer Capability: Rare in the AM industry—developed and validated in-house

- Scalable & Distributed Production Model: Print locally, scale globally

- Design + Materials + Manufacturing = Speed-to-Mission

Applications

- Aerospace structures & brackets

- Battery enclosures & electronics packaging

- Composite tooling & layup forms

- Conformal warfighter gear

- Replacement parts for obsolete or hard-to-find systems

Connect With Us

Whether you’re seeking prototyping support, mission-grade production, or a trusted partner for secure manufacturing, CRG Defense delivers.

Contact Us