Secure, Scalable Production for Advanced Defense Platforms

The Materiel Division at CRG Defense delivers mission-critical parts, structures, and tooling across air, land, and sea domains. We integrate advanced manufacturing methods—including additive manufacturing, compression molding, and proprietary processing—to support the DoD’s need for scalable, secure, and rapidly deployable hardware. Whether for first article production or full-rate sustainment, our vertically integrated capabilities support rapid iteration, low-rate initial production (LRIP), and classified or proprietary material development—all under one roof.

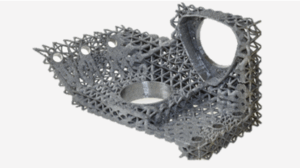

Additive Manufacturing

With large-format, high-temperature additive manufacturing (including ULTEM™, PEEK, and carbon-filled polymers), we produce complex components at speed and scale.

Read more about Additive Manufacturing

Contact UsDesign Services for Additive Manufacturing

Our expert design and prototyping team will help you accelerate development of innovative, high-performance parts and products for fast market delivery. Our proprietary design for additive manufacturing (DfAM) computational optimization toolset, LattiSolve, can simultaneously optimize for weight reduction, structural integrity, thermal management, and vibration control.

Sustainment Product Line

Our DIRT Bag® system revolutionizes sustainment for aircraft and vehicles by capturing particulate contamination at the source—extending component life, reducing maintenance, and supporting long-term readiness. Designed with warfighter input and funded by AFWERX, this dual-use solution is field-ready and platform-flexible.

Secure Manufacturing of Proprietary Materials

We specialize in secure, ITAR-compliant manufacturing for proprietary and/or sensitive materials and components.

Materiel Division News

- CRG Defense adds ARGO 500 HYPERSPEED to expand manufacturing-grade additive production

- CRG Defense featured in Composites World and Dayton Daily News

- CRG Defense Expands Additive Manufacturing with ARGO 1000 HYPERMELT

- CRG secures $2.5 million Air Force contract to develop next-generation high-temperature 3D printer for aerospace

- CRG awarded patent for rapid method of manufacturing composite aircraft structures

- CRG’s composite material aboard MISSE-19 for space durability testing

Looking for vertically integrated production with mission-ready speed?

Work with our Materiel Division.