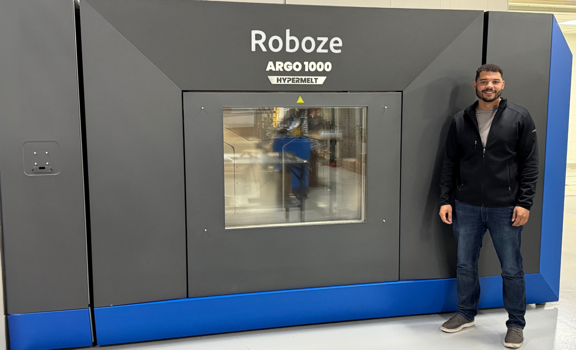

CRG Defense has become one of the first companies in the world, and only the second in the U.S., to acquire the ARGO 1000 HYPERMELT, a large-format 3D printer from Italian manufacturer Roboze. The system enhances CRG Defense’s ability to produce aerospace-grade polymer and composite parts at scale and serves as a powerful new asset for partners seeking to enter or grow within the U.S. defense and aerospace sectors.

The ARGO 1000 HYPERMELT uses Fused Granulate Fabrication (FGF) to produce high-performance thermoplastic components with exceptional accuracy and repeatability. Its build volume of 1000 x 1000 x 1000 mm (approximately 39 x 39 x 39 inches) allows for the production of large, complex parts and assemblies that meet demanding aerospace requirements. Accuracy, repeatability, and reliability are key differentiators of this new capability, enabling both advanced applications and larger-scale manufacturing efforts.

“This gives us immediate production capability while we continue developing our next-generation additive manufacturing technologies,” said Ian Fuller, Strategic Director and Additive Manufacturing area lead at CRG Defense. “It also allows us to support organizations that want to bring advanced materials, such as fiber-reinforced PEEK, PEK, and PEI, into secure production environments without building that infrastructure from scratch.”

The acquisition builds on CRG Defense’s ongoing $2.5 million U.S. Air Force contract to design a large, ultra-high-temperature 3D printing system for future aerospace applications. That project, funded by the Air Force Rapid Sustainment Office, focuses on producing components capable of withstanding extreme operating conditions at a scale previously not achievable with additive manufacturing.

In parallel, the ARGO 1000 HYPERMELT provides a fully operational, production-ready solution that can meet today’s manufacturing needs in defense, aerospace, and adjacent industries such as oil and gas, motorsports, and automotive.

CRG Defense offers more than technical capability; it also provides a fast track into defense manufacturing. With existing contract vehicles, long-standing partnerships, and a secure, U.S.-based production environment, the company enables commercial innovators and foreign-friendly firms to transition their technologies into government programs without starting from scratch.

“The ARGO 1000 HYPERMELT represents a strategic leap forward in our additive manufacturing capabilities.” Fuller said. “It complements our existing projects and allows us to offer a unique value proposition to our partners: cutting-edge research combined with immediate, large-scale production capacity in a secure environment. We have already demonstrated these advantages through the development and manufacture of multifunctional composite layup and debulking tools for aerospace customers.”

For partnership inquiries or to discuss additive manufacturing opportunities, contact sales (at) crgdefense.com or Contact Us

About Roboze: Roboze is a leading company in the development and production of advanced solutions in the field of industrial 3D printing. Founded with the aim of transforming how companies design and produce components, Roboze offers comprehensive solutions for additive manufacturing with super polymers and composite materials, enabling applications in sectors such as aerospace, mobility, energy, and manufacturing. Roboze’s mission is to accelerate the adoption of 3D printing through continuous innovation and the provision of reliable and sustainable solutions. For more information, visit www.roboze.com.